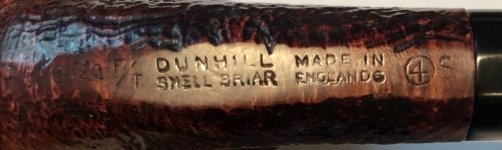

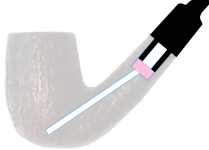

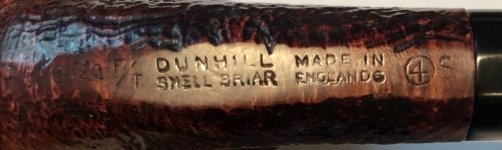

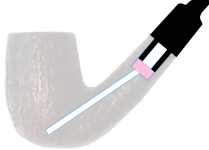

Picked this up from Rich at Briarville. Birthyear and my first Dunhill. Passes a pipe cleaner (with a bit of a twist to find the shank bore). Curious about the number. 6120 suggests a Group 6 cherrywood in the charts I could find, but it ain't that... Has a 4S stamp which says group 4...but it is a taller bowl so maybe group 6 capacity with a group 4 diameter? Chamber is .80" diameter, 1.95" deep. Anyway, here are some pics, as well as a depiction of a potential gurgle chamber (in pink)... the stem goes in 12.5 mm of an 18mm deep mortise. Is this typical of Dunnies of the time?

Last edited: