Patent Era Pete In Tough Shape!

- Thread starter MavErik

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I can hear "Taps" playing in the background and they are not soft.

Fireplace mortar, hose clamp and a tub of carter hall will sort that for you mate

Clearly this thing is used to being abused. I’d say load it up with your favorite blend and give it what it’s used to!

Clearly this thing is used to being abused. I’d say load it up with your favorite blend and give it what it’s used to!

I was thinking along the same lines. Hell, nothing I do to her can come close to what’s already taken place by it’s former owners.

A good cleaning, some pipe mud and see how she does. I’ve never smoked a 100+ year old briar before!

Heading to Home Depot now!Fireplace mortar, hose clamp and a tub of carter hall will sort that for you mate

She's my favourite Argentine Tango dancer.

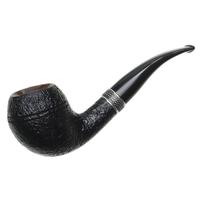

You could do what I did with this patent era Dunhill. The bowl was toast but the shank and stem were salvageable. So I cut off the shank at an angle where it met the bowl and glued on a cob bowl. Some stain, polishing and wax later, presto a Duncob! Finding the right cob bowl would be the tricky part due to the shape of the pipe, but I think it could be done with a larger cob bowl. Just something to think about.

Brilliant!You could do what I did with this patent era Dunhill. The bowl was toast but the shank and stem were salvageable. So I cut off the shank at an angle where it met the bowl and glued on a cob bowl. Some stain, polishing and wax later, presto a Duncob! Finding the right cob bowl would be the tricky part due to the shape of the pipe, but I think it could be done with a larger cob bowl. Just something to think about.

View attachment 285675

View attachment 285676

But I think Alfred just spun around in his grave.

Brilliant!!You could do what I did with this patent era Dunhill. The bowl was toast but the shank and stem were salvageable. So I cut off the shank at an angle where it met the bowl and glued on a cob bowl. Some stain, polishing and wax later, presto a Duncob! Finding the right cob bowl would be the tricky part due to the shape of the pipe, but I think it could be done with a larger cob bowl. Just something to think about.

View attachment 285675

View attachment 285676

Well done sir ! The most agreeable "Frankenpipe" I've seen in ages !You could do what I did with this patent era Dunhill. The bowl was toast but the shank and stem were salvageable. So I cut off the shank at an angle where it met the bowl and glued on a cob bowl. Some stain, polishing and wax later, presto a Duncob! Finding the right cob bowl would be the tricky part due to the shape of the pipe, but I think it could be done with a larger cob bowl. Just something to think about.

View attachment 285675

View attachment 285676

How did you manage to clue it so neatly ?

I prefer fiery women.She's my favourite Argentine Tango dancer.

I used regular wood glue to glue the shank inside the bowl, then used some pipe mud around the bottom. Then I used JB Woodweld to fill in the gap on the outside of the bowl. Careful sanding, staining and finishing took care of the rest.Well done sir ! The most agreeable "Frankenpipe" I've seen in ages !

How did you manage to clue it so neatly ?

Congrats on a great job; this is what I like on the forumI used regular wood glue to glue the shank inside the bowl, then used some pipe mud around the bottom. Then I used JB Woodweld to fill in the gap on the outside of the bowl. Careful sanding, staining and finishing took care of the rest.

JB Woodweld is new to me , what is the difference ?

I wonder if it could be used as a pipe cement ?

As is often done ( not by me ) with the regural weld.

I'm not sure what you mean by pipe cement. Are you thinking of what you would use inside of the bowl? If so, I don't think it would be advisable as it is an epoxy much the same as regular JB Weld. I have found it to be pretty good for patching cracks etc. on the outside of pipes, although it's not really stainable. I end up using super glue with briar dust, or simply use stainable wood putty as the finish filler. Mind you, this type of repair is mainly used for badly damaged pipes that would have no value to begin with. It's just fun to repair these hopeless pipes sometimes.Congrats on a great job; this is what I like on the forum

JB Woodweld is new to me , what is the difference ?

I wonder if it could be used as a pipe cement ?

As is often done ( not by me ) with the regural weld.

Nobody recommends duct tape and bailing wire?

Bunch a' city slickers.............

Bunch a' city slickers.............

Take a look at a product called Durham's Rock Hard Water Putty - it has the interesting property of not shrinking when it dries. It doesn't stain well though...

Perfect!You could do what I did with this patent era Dunhill. The bowl was toast but the shank and stem were salvageable. So I cut off the shank at an angle where it met the bowl and glued on a cob bowl. Some stain, polishing and wax later, presto a Duncob! Finding the right cob bowl would be the tricky part due to the shape of the pipe, but I think it could be done with a larger cob bowl. Just something to think about.

View attachment 285675

View attachment 285676